1000X1000mm Filter Plate Filter Press Why BBNEP filter press has longer service life?

Henan BEBON Intelligent Environmental Protection Engineering Technology Co., Ltd regards “change sewage into clear water, convert sewage into resources” as our task. We have provided filtering equipment for hundreds of customers from sand-washing industry, chemical industry, sewage treatment plant and so on. In addition, we have our own laboratory and development team. According to different features of wastewater, we will recommend our customers suitable filtering equipment, so as to optimize filtration effect. We will try our best to realize zero discharge of wastewater.

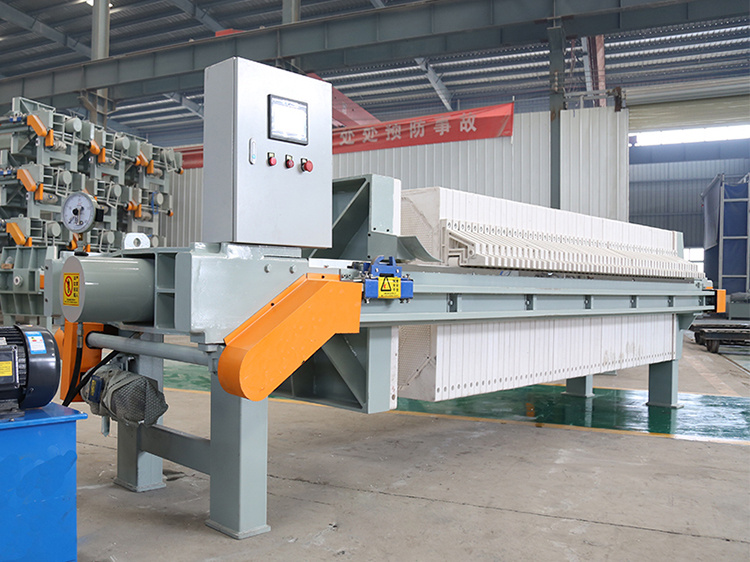

1000X1000mm Filter Plate Filter Press,The filter press adopts the external pressurization method to force the solid liquid separation in the sludge, which greatly shortens the filtration cycle. The pressure during filtration is high, and the treated mud cake is very dry. For some mud that needs to be dried again, the drying consumption is reduced. The machine adopts special treatment, which is not easy to be corroded. The advanced technology of the sealing ring and other equipment is introduced, and the sealing performance is better, which ensures the sealed space during filtration and makes the sludge treatment effect better.

BBNEP owns special manufacturing technology of filter plates. From raw materials (Polypropylene), heat with high temperature, compression molding forming, polish, drill hole to final product, each process are in charge of specialized operators. Processed filter plates has smooth surface, which can guarantee good sealing. In addition, our filter plates are made up of quality PP, and they are white and have no abnormal odor.

BBNEP mechanical filter presses use electrical machinery to drive the keep plate to compress the filter plate to form a closed filter chamber After the filter plate is pressed tightly, the material enters the filter chamber composed of the filter plate Under the action of the mud pump, the liquid passes through the filter plate and enters the liquid outlet channel along the filter plate groove, and is discharged out of the machine The solid material is trapped in the filter chamber due to its large diameter With the continuous input of materials, solid particles gradually accumulate to form a filter cake When there is no longer filtrate flowing out, you can turn off the feed pump, loosen the filter plate, and manually pull the filter plate in sequence to discharge After the discharge is completed, the filter plate can be pressed again for the next round of pressure filtration,1000X1000mm Filter Plate Filter Press.

Comprehensive and timely service is the lifeline of BBNEP BBNEP optimizes the opportunity for sincere cooperation, common development and double-win, serving hundreds of companies across the country We try our best to help customers save costs and improve working efficiency Satisfaction is always our persistent pursuit,1000X1000mm Filter Plate Filter Press.

BBNEP consulting service team provides customers with cash production solutions. The company's research laboratories and laboratories conduct scientific research and analysis on different materials in different industries to design reasonable production technology solutions. We set up the Engineering Technology Department. According to customer needs, design scientific engineering and technical solutions to create advanced, reasonable and optimized production processes for customers.